ESDEP WG 1A:

STEEL CONSTRUCTION:

ECONOMIC & COMMERCIAL FACTORS

To introduce the different factors affecting the cost of a steel construction. To show how the factors are considered in developing a design taking into account technical and recurrent and environmental costs.

None.

Lecture 1A.1 : European Construction Industry

Lecture 1B.1 : Process of Design

Total costs of a steel construction are affected by technical and environmental factors and recurrent costs. The steel costs, the energy, maintenance, adaptability and end of life costs must all be appreciated from the very beginning of a project in order to lead to a well designed construction, which meets the requirements of the client. Different parameters such as speed of construction, or choice of foundations are studied so that they may be taken into account in the design of the construction and in determining its cost. Secondary activities such as erection, fabrication and protection against corrosion and fire complete this analysis.

Costs of construction works can be considered in various categories. Technical costs, relating to material and labour in completing the project, are those which can most easily be quantified. Recurrent costs should also be considered in studying whole life economics, and again these can be estimated. Environmental costs are more difficult to establish; there are signs that an environmental audit will increasingly be required as a part of the consideration given to proposed projects. Environmental aspects can be considered in terms of local and global effects and include issues such as appearance, safety, local economics, use of natural resources, and energy consumption.

This lecture concentrates on the technical costs of steel construction. It deals with the topic in a broad way. Whole life costing is dealt with first before examining the costs of execution, which are concerned initially with total construction, leading onto structural costs and finally economic considerations applied to individual activities such as fabrication and erection. This sequence has been chosen deliberately to emphasise the need to examine overall costs in an integrated manner.

Traditionally designers have considered only the initial cost of that part of the project for which they are responsible and have sought the most cost-effective solution for it. There is increasing recognition that the sum of optimum cost components do not necessarily lead to the most economic solution overall. However, there is still relatively little regard given to whole life costs. This is in marked contrast to the consideration given to running costs when purchasing a new car, for instance. Then fuel consumption, likely service costs, repair costs and depreciation are often carefully accounted for alongside initial price, when making cost comparisons between different models.

Initial costs of execution, including the fabric, structure, foundations and services, are an important and immediate consideration. In addition to these items, the need to finance the construction, and the associated costs, should be quantified and included as part of the debate on the form of the design. The way in which the cost of finance influences the project is discussed in more detail in Section 3.2. In some cases, it might be a major factor.

Other recurrent costs, which should be considered in the overall economic discussions surrounding a proposed project, include maintenance, future alterations and running costs associated with environmental control of building interiors (heating, ventilation and lighting). Another factor which should be considered is the likely benefit or financial return. For instance, projected traffic density will clearly be an important influence on required highway bridge capacity, whilst clearer floor areas and greater flexibility in the use of floor space may attract higher revenue in commercial developments. These factors are discussed in more detail in Section 2.6.

Energy costs for lighting, heating and ventilation remain a significant recurrent cost item. For buildings, initial expenditure related to energy requirements is concerned with such aspects as the balance of provision of natural and artificial lighting, and the heating/ventilation requirements, which are clearly affected by the insulation specification for the external skin.

Artificial lighting represents a surprisingly high proportion of energy consumption in commercial and residential buildings. Adequate provision of windows and rooflights can therefore mean significant long-term savings. These provisions need to be assessed against higher initial expenditure, and secondary considerations, such as security. Heat gain and glare are two potential problems which should also be considered since they may effectively neutralise any potential savings.

Space heating and ventilation are both related to insulation levels and the volume of air to be treated. One of the reasons why low-pitch portal frames have become more popular than the traditional column and truss construction for industrial applications is that the enclosed building volume is reduced and includes very little wasted space.

All structures (buildings, bridges and others) should be inspected and maintained on a regular basis. There is often a trade-off between costs associated with these activities and initial costs. Areas which are difficult or impossible to inspect need careful treatment. In many cases there is a trade-off between capital expenditure and life expectancy/maintenance requirements.

For steels, corrosion and its prevention is a major concern. Cost factors associated with corrosion prevention relate to exposure conditions, planned inspection and maintenance, design detailing, the protection specification, and the quality of the first application.

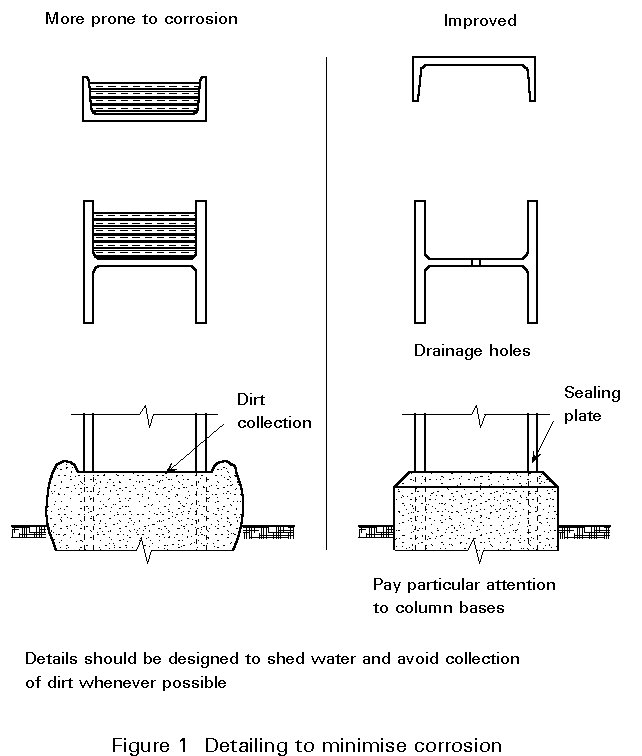

Good detailing in fact has very little cost implication and is an important part of all designs. For instance, arrangements which allow water to collect should be avoided and inaccessible areas sealed (Figure 1).

The specification for the corrosion protection system should be appropriate to the exposure conditions expected. Although some extremely good systems are now available, there is little point in using such systems where corrosion risks are low. This point is discussed in more detail in Section 4.3.

Although it is not always possible to predict future client requirements, alterations and extensions to projects are often carried out subsequent to the initial development. Such projects can be disproportionately expensive. Specific provision for future alterations can only be made if details are known at the outset, but significant savings are possible if the original design takes account of possible changes. Although the initial development costs may be marginally increased, long-term costs overall can be reduced.

The building life is always longer than the life expectancy of services, so the construction should be able to accommodate likely changes in use. This capability can be provided by adopting a "loose fit" approach, giving additional space without disproportionate increase in cost.

Shell and core construction, in which the building consists of the structure and major services only, with the more specific services for floors installed by the tenant, is becoming increasingly popular for speculative commercial developments. In such cases there is an even clearer need for a "loose fit" approach from the outset.

It is very common for the use of building to change. Change of use may require upgrading floor loadings, modifications to floor layouts, installation of new lifts, or extending the structure to provide more usable space. Allowing for such developments in the original design could lead to significant subsequent savings.

Steel structures can be adapted or extended without great difficulty. The potential exists for making connections to the existing frame, and the strength of the existing structure, and any new attachments to it, can be determined with confidence. Nevertheless, where future changes are envisaged, it is often more efficient to provide for these at the outset. Where future extension is planned, simple modifications to the fabrication details and appropriate sizing of critical members for the new conditions should be incorporated. For instance, pre-drilling of steelwork for new connections at the interface with the possible extension and sizing columns for increased loads facilitates later construction.

If unforeseen changes arise, it is not difficult to strengthen individual beams and columns, for instance, by attaching flange plates to the existing section. Strengthening connections is very much less simple, and some designers therefore overspecify the shear capacity for connections to minimise the need for strengthening in subsequent alterations.

Costs should not be considered in isolation but set against perceived benefit. The benefit may be clearly quantifiable in terms of rental income or relate to the provision of additional facilities. In either case usable floor area is a key factor. This might suggest fewer, smaller columns, and should certainly encourage the designer to avoid unusable space, for instance between columns and adjacent perimeter walls. Minimising the thickness of partition walls and the external skin may also yield an increased floor area, but their performance should not be compromised in doing so.

For many structures there comes a time when demolition is necessary. The cost associated with this activity can be offset by income from the sale of recyclable materials. For steel structures the material can be re-used either as scrap in the manufacture of liquid steel or as secondhand products which can be re-used in new structures. The nature of steel construction lends itself to dismantling rather than demolition.

Some structures take this principle further and are designed as demountable. Such structures are generally for short-term use such as exhibition facilities, temporary car parks and highway crossings. With careful design the complete structure can be dismantled and erected elsewhere.

Total building cost is a complex issue due to the interaction of various elements. Usually the best design of one aspect (e.g. structure) conflicts with others (e.g. services or cladding). It is not, therefore, simply a case of optimising each to achieve an optimum solution for the whole building, but rather the costings should be examined in an integrated, holistic manner.

Buildability is also important. It is concerned not simply with the development of new details or erection systems which might facilitate work on site, but with an understanding of how design and construction can be dealt with in an integrated fashion to produce a building which is simple, quick and cost-effective to execute and maintain. This approach involves harmonisation of structural, service and planning grids.

At a more detailed level, standardisation, particularly of connection and fixing details, can lead to significant economies, even if it implies some apparent wastage of materials. Co-ordination between different elements, such as cladding and structure, achieved by simplicity of the interfaces between them, is particularly important. Non-typical areas such as corner panels for cladding and edge details for floors need special consideration. All too often these areas are ignored until execution is well under way and last minute solutions can be both inelegant and costly.

Bridges and other structures are much less sensitive than buildings to interactions between structural and non-structural components. However, for offshore structures for instance, aspects such as appropriate construction sites and transparency of the structure to wave loadings, installation procedures and fitting out all influence the total costing.

An important cost element in a steel framed building is that of the frame itself. Other major items include foundations, flooring, cladding/external finishes and services. The relative contributions of these items vary considerably from one project to another, but typical cost proportions are 9% for the steel frame compared with 25-35% each for cladding and services. Land prices can sometimes be as high as the direct costs of the construction, in which case speed of execution becomes a predominant factor as discussed in Section 3.2.

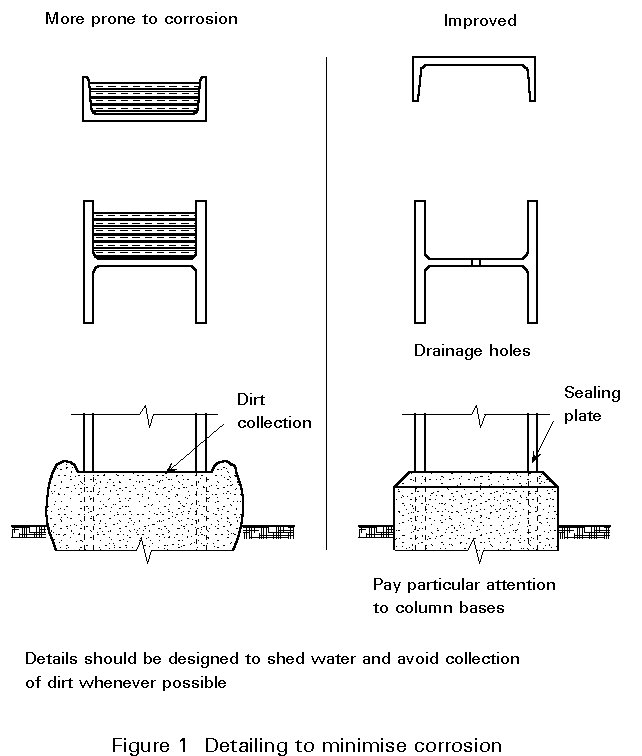

For multi-storey buildings, the importance of lateral bracing becomes a primary consideration. For low-rise construction, a rigid jointed frame is often an economic solution, but as overall height increases, this system becomes too flexible. Cross-bracing or shear walls might then be preferred, despite possible restrictions on internal planning imposed by the location of the bracing. With greater building heights, more sophisticated lateral bracing systems become necessary. These systems include derivatives of both rigid frames and cross-bracing such as outrigger trusses, braced tubes and facade frames. Some of these systems are shown in Figure 5 which includes indications of their appropriate ranges of use.

A similar discussion of the use of rigid and simple frames can be held in relation to gravity loads. The effect of rigid frame action is typically to reduce beam sizes but increase column sections. In general, whilst the total weight of steel is less in rigid construction, savings are often more than offset by the increased complexity of the connections. However there may be other considerations - reduced structural depth, the undesirability of bracing (if rigid frame action is not used to provide lateral stability) and reduced deflections resulting from improved stiffness. For longer spans, material savings for rigid construction are likely to be greater. Not only does the increased rigidity become more important in controlling deflections, but the relative saving in steel weight of beams compared with the increased weight of columns becomes more significant.

Important advantages of steel construction are speed of execution, prefabrication and lightness. To maximise the advantages the concepts must be followed through in the design of the building as a whole, including cladding, finishes and services. For example the use of smaller foundations can only be achieved if the lightness of the structure is reflected in appropriate design of other building components. This example again emphasises the need for co-ordinating the design of services, cladding and structure and associated with this approach, the discipline of producing the final design at an early stage.

This approach also implies that the steelwork contractor should be involved at the earliest opportunity as part of the project team and it also places additional responsibilities on other members of that team to avoid late changes.

The costs of financing a project may be a major consideration. High land prices and staged payments to the contractor mean that the client may have to sustain a high borrowing requirement throughout the period of execution without any return in terms of either rental income or use of the building. With high interest rates the borrowing requirement can represent a major element in the total project cost and, under these circumstances, the speed with which the project can be completed becomes an extremely important factor.

The importance of speed has been highlighted in a comparison of costs for typical 3, 7, and 10-storey office buildings using three different building systems (steel frame and precast concrete floor, steel frame and composite floor, and in-situ reinforced concrete). Construction programmes and cost estimates prepared independently for each building clearly showed the importance of execution time. The study also demonstrated the benefits of steel deck composite flooring in avoiding the need for temporary propping or scaffolding, the advantages of simplicity, and the need to ensure that various trades are able to complete work at one level in a single operation. Providing access by programming staircases to rise with the frame and installing floors as quickly as possible after the frame also streamlines site work.

The trend towards greater prefabrication and sub-assembly with reduced site work has spread from simply the steel frame to include other elements such as cladding panels and accommodation modules. Prefabrication all helps to save execution time but it places more pressure on the design phase. It also improves quality, reduces reliance on a skilled, mobile workforce, and enables deficiencies to be rectified more easily than on site. Precommissioning should also produce a greater awareness of, and provision for, future maintenance requirements.

Late changes and traditional reliance on resolving problems on site may be suitable for insitu construction. However, more emphasis on prefabrication in modern construction means that the site becomes an assembly shop where the components must fit first time if expensive delays and corrections are to be avoided.

Fast build rather than fast track is perhaps the optimum solution. In the latter the construction programme overlaps with the design phase, implying incomplete information. In contrast fast build construction does not start until all design is complete, and embodies the best features of efficient building.

Any construction can be affected by adverse weather. Execution programmes and methods themselves are generally organised with this in mind. For instance when industrial sheds are built it is normal practice to complete the frame and envelope at the earliest opportunity, with the concrete ground slabs subsequently being cast within a relatively controlled and sheltered environment. Multi-storey construction utilising composite floor decks offers similar advantages of rapid isolation from the worst effects of adverse weather.

Some building systems have been developed on the basis of providing a dry envelope for the work of execution.

The greatest cost interactions between building components are probably those between structure, main services and cladding. The total floor depth includes the structure (slab and beam) and services. The greater this depth the greater will be the total height of the building, increasing the area of cladding. Even for simple enclosure systems, increased costs will result. For sophisticated curtain walling systems these increases could be very high. In extreme cases, where planning constraints are particularly severe with regard to total building height, it is possible that the selection of a shallow floor zone could result in the inclusion of an additional storey compared with the case for a deeper floor construction depth.

Smaller scale services (electrics, telecommunication wiring) can be accommodated within raised floors, or in trunking set in the screed or within the structural concrete slab. They have little implication for the structure. Large ducted air conditioning systems involve greatest interaction. Here the objective is to produce an efficient floor structure, which can accommodate the required size of ducts (including cross-overs), and which also allows the addition or increase of sizes as servicing needs change.

Possible strategic solutions are separation or integration. Separation gives greatest flexibility and provision for future changes. Allowing the services to pass through the structure may result in some savings in overall construction depth but installation may be difficult and cause possible damage to paint and fire protection; future changes may also be limited.

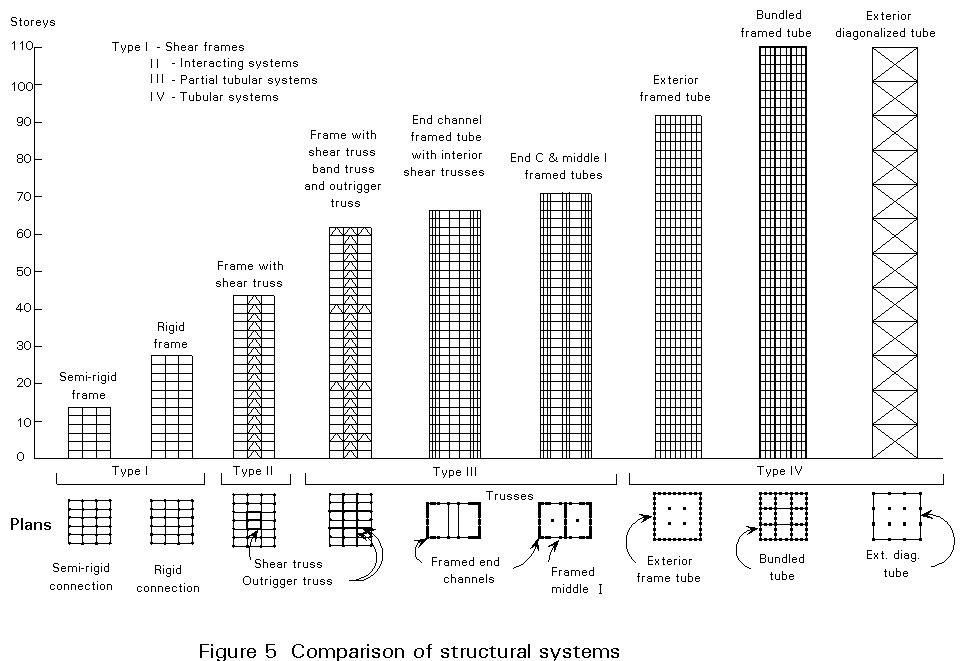

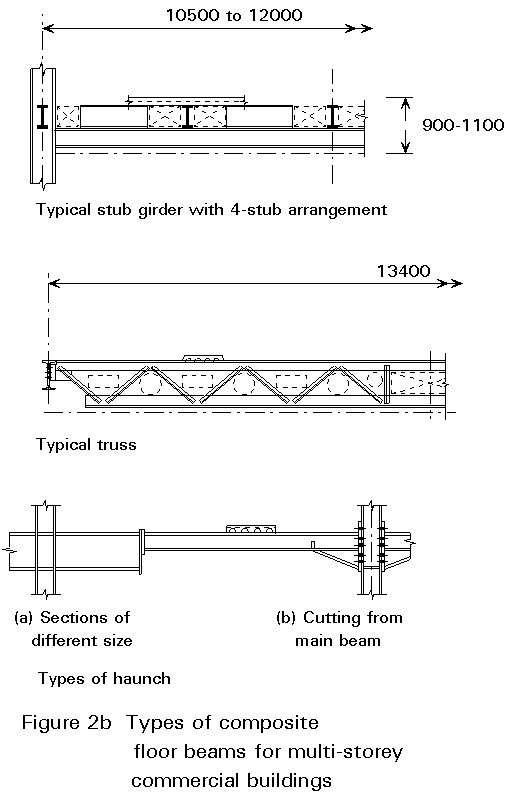

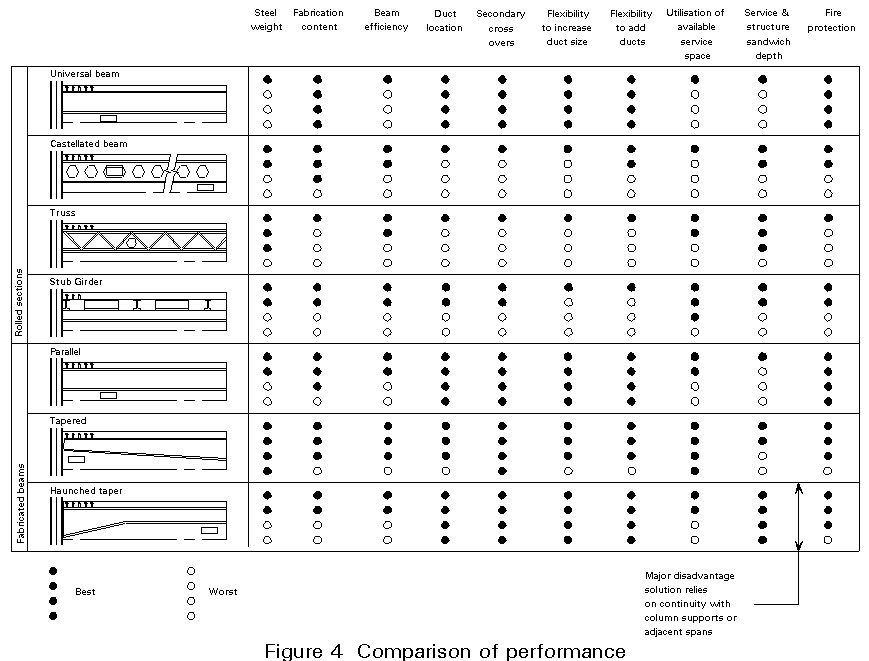

Structural forms to facilitate accommodation of services relate particularly to different arrangements of beams. There is generally much more space available between beams where only slab depth contributes to construction depth. Possible solutions (Figure 2) include standard I beams, castellated beams (which, although deeper, provide limited opportunity for accommodating service ducts), trusses and stub girders (both deeper again but with greater provision for ductwork). The parallel beam arrangement, which separates on two levels both structure and service runs in two directions, has proved to be a successful solution for a number of projects (Figure 3). Other possibilities include various forms of tapered and haunched beams, used to optimise overall depth and structural efficiency, but at the expense of greater fabrication costs (Figure 4).

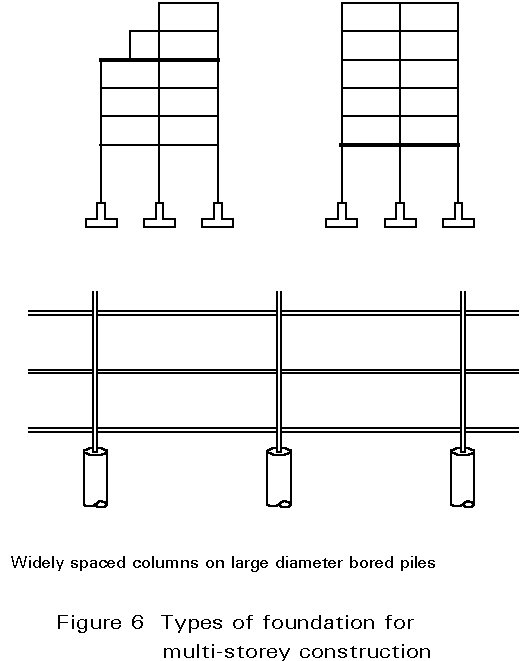

Foundation costs are an important factor in the overall economics of building construction. For small scale buildings on sites with good foundation conditions, simple foundation solutions are likely to be suitable. Where foundation loads are high and/or foundation conditions are poor, more sophisticated and expensive solutions such as piling may be necessary, Figure 6. In such circumstances the weight of the superstructure may be critical and suggest a lighter, possibly less efficient form. For instance closely spaced beams to reduce the thickness of floor slabs, which might themselves be constructed using lightweight concrete can reduce foundation loads considerably. Steel as a structural material is also lighter than other structural materials for a given load resistance.

At a more detailed level the economics of steelwork construction can be affected by decisions regarding the precise form of element, type of steel used and the method of connection. Some of these decisions are influenced by the purchase route for the steel itself. For large projects, steel can be purchased directly from the mill in the exact lengths required and in the desired grade. The price of individual structural products varies not only with type (hollow sections are generally more expensive than open sections such as I-beams and H-columns) but also within a product range, with little apparent rationale behind the pricing policy. Thus selecting a section of minimum weight does not guarantee an optimum solution in terms of cost, even for an individual element. Specifiers should therefore be aware of pricing policies.

Small orders cannot be processed in this way and the steel is then purchased from stockholders. In this case the steel is only available in a limited range of grades, (probably only mild steel) and a premium is payable to the stockholder. In addition certain sizes of standard section may not be stocked and the sections will only be available in a limited range of lengths.

These considerations clearly have important implications for the specifier.

Where higher grades of steel are available they may offer the opportunity for improved efficiency. For instance, high yield steel has a yield strength approximately 25% higher than normal mild steel yet costs only about 10% more. However, where strength is not a critical design condition, for instance in the case of very long span beams where deflection control may be dominant, the use of high grade steel may simply be wasteful.

A breakdown of costs for structural steelwork in a multi-storey building might typically be as follows:

|

steel |

47% |

|

corrosion protection |

5% |

|

fabrication |

22% |

|

erection |

8% |

|

fire protection |

18% |

Clearly optimising the cost of the steelwork (within an optimum solution for structure and construction as a whole) is dependent on minimising the total cost of these contributory elements, rather than optimising each independently. A balance is needed between structural efficiency, simplicity of construction and building use.

It is clear that there is more potential for reducing costs in fabrication and erection than in the steel itself. In this respect, work on site is of most importance - easier assembly is likely to lead to overall economy. Transport is also important, not as a cost item in itself but as an aid to more efficient erection.

Because erection is carried out in the open, often under difficult conditions, and it is the essential interface with other construction trades, it is in many ways the most important part of the design and execution process for a steel structure. Problems at this stage can be costly to rectify and involve long delays to the programme. Apparently trivial issues, such as steelwork delivered out of sequence, lack of bolts or fittings, long lead times for minor additional items, extensive double handling of materials and misfit of members, can cause significant reductions in construction efficiency.

Much depends on good planning. Preparation of an erection scheme should be made on receipt of first construction issue drawings prior to detailed drawing office work by the fabricator. At this stage items for delivery as sub-assemblies can be identified and the need for temporary bracing assessed. Attachments for bracing should be incorporated within initial fabrication drawings to avoid double handling of both drawings and materials.

The need for safe access for erectors must be recognised. Time can be saved and material re-used if temporary stagings are pre-engineered and delivered with steelwork rather than relying on makeshift methods on site.

Loose temporary landing cleats under major beams and girders, shop-bolted to columns greatly facilitate erection. Erection drawings should be clear, unambiguous and complete, including on a single drawing all details such as bolt sizes, weights of members, presence of fittings, etc.

The size of individual components is limited by the lifting capacity of available cranes and transportation. This applies also to other parts of the construction such as finishes and cladding. Within these constraints however the general principle is to maximise work at the fabrication stage and minimise work on site, pre-assembling units in sections which are as large as possible.

Connection design and detailing which standardises details, bolt diameters and lengths (HSFG and 8.8 bolts of same diameter should never be used on the same job) simplifies erection and minimises risk of error. Although material and fabrication costs may be increased marginally, savings on site far outweigh such increases. Simplicity and repetition of frame components is related to design; for instance special fabricated sections such as tapered beams become more economic in larger numbers.

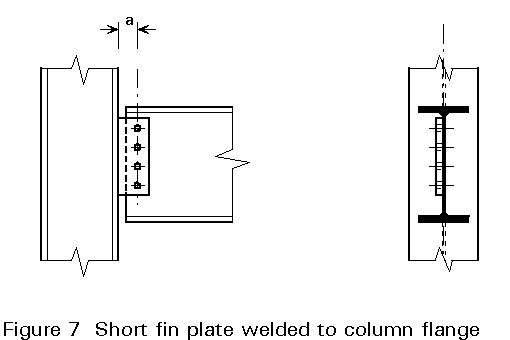

Preferred details should be incorporated to facilitate site erection. For instance fin plates are preferable to end plates or cleats since they enable beams to be swung directly into position (Figure 7). Moment connections should be avoided if possible, but where necessary the erector should be consulted with regard to the preferred type of detail.

A loading schedule should be prepared by the erector showing when steel is to be delivered, how it is to be bundled, where to be placed on the trailer for optimum off-loading and where to be set down in its correct location on the building frame. Lack of vigorous production control often requires a buffer store on site to maintain the erection programme. This procedure is inefficient in terms of storage space, cranage and multi-handling. Programmed site erection should be the control and 'pull' on fabrication, with delivery scheduled to accord with the daily erection programme. One of the most notable examples of erection programming was the construction of the Empire State Building in New York.

There is a clear need for a production engineering philosophy in the design office, factory and on site. For example, a careful study of the fabrication process can significantly reduce material handling. The productivity of the most efficient shops is based on a labour content of 2 man hours per tonne for simple multi-storey construction compared with more than 20 man hours per tonne average for all steelwork.

Some structurally efficient solutions, even based on standard rolled sections, may be less efficient in terms of fabrication. Column sections with bigger overall dimensions generally have larger radii of gyration and hence, for a given application, have lower slenderness ratios and higher buckling strength; they may therefore be lighter in weight than a comparable section of more compact shape. Where these sections are used as part of a moment resisting frame, however, the reduced flange thickness of the bigger section may well mean that local stiffening is required, increasing fabrication costs.

Computer controlled cold sawing, punching and drilling machines mean that bolting for low to medium rise construction is often cheaper than welding which involves more labour, cost and time. This is particularly so on site where special access, weather protection, inspection and temporary erection supports are required.

Linking of CAD/CAM and management information systems avoids transcription of information, saving time and eliminating possible errors.

The cost of initial corrosion protection is unlikely to be greatly influenced by the steelwork details, although maintenance costs and performance can be significantly affected. Appropriate specification of the corrosion protection system is important. Steel within a heated building is unlikely to need any long term protection at all, whereas exposed steel or steel within the external envelope may need a high level of protection. Detailed advice is available. Painting costs are partly dependent on the area to be painted, whilst galvanising costs are related to the weight of steelwork. The latter therefore becomes a more attractive alternative for lightweight structures with a large surface area such as trusses and lattice girders.

Regulations relating to fire protection requirements now allow calculation methods to prove reduced or indeed the elimination of such protection. A range of relatively cheap, lightweight proprietary systems is also available and, if these systems are adopted, performance, appearance, and wet or dry application influence the final selection. Some structural solutions such as slimfloor beams offer the potential for adequate fire resistance without protection. Although the weight of steel is greater than for conventional systems, the overall effect may be some savings. In addition, slimfloors offer a reduction in structural depth and are, therefore, attractive in terms of accommodation for services.